Case study: accelerators for building a car

Case study: Accelerators for building a car

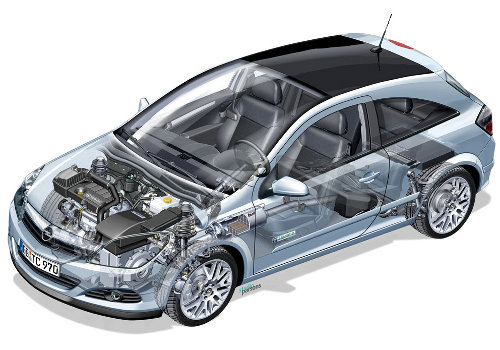

Many industrial applications of particle accelerators are particularly useful for the automotive industry. Indeed, components such as tyres, foam, ball bearings, gears, camshafts and tie-rod ends are produced using either electron beam thermal processing or irradiation. Modern ion implantation systems make the advanced electronic systems in cars possible.

Case study: accelerators for building a car (2)

Image credits : Car, engine, wheels: 2007 Opel Astra GTC Hybrid concept by Studio Parsons for Adam Opel AG | Dashboard: Adam Opel AG | Car interior: Adam Opel AG | Suspension: 2CarPros.com

The list of items in the case study above and in the table below is not exhaustive. Surface hardening can benefit any object that undergoes stress, extreme temperature or experiences wear. Most of the moving parts in a car could benefit from surface hardening and from new methods like ion implantation and material irradiation.

Some items in the above list may not currently be used in car manufacturing, such as carbon fibre cassis, but are on the horizon of future developments in the manufacturing industry. Other potential advances not included on this list are in the area of alternative fuels. Advances in hydrogen fuel and hydrogen fuel cell technology could see hydrogen powered cars become a reality in the future. Research into this is being carried out around the world and synchrotron radiation generated by particle accelerators is one of the key tools. Also biofuel researchers have found that treating fuel with electron beams can improve its quality.

In summary

|

Industrial process |

Car part |

|

|

Electron beam material irradiation |

Cross-linking of polymers |

High Performance Electrical Wires Insulation |

|

X-rays curing of composites |

Fender |

|

|

Electron beam material processing |

Welding |

Gears |

|

Heat treating |

Cam shaft |

|

|

Ion implantation |

Ion implantation into semiconductors |

Electronics |

|

Ion implantation into metals |

Cam shaft |

|

Main resources

Below is a list of the articles used as reference to write this page. For anyone looking for more information on the role of particle accelerators in the building of a car both now and in the future, it can be found in the links below.

Wire and Cable Insulation

Article (symmetry) [2010]: Accelerator Apps: Heat-shrink tubing

Doc (IAEA) [2004]: Emerging Applications of radiation processing, p119

X-Ray Curing

Doc (IAEA): Radiation curing of composites for vehicle components and Vehicle manufacture

Electron Beam Welding

Web (Cambridge Vacuum Engineering): Turbochargers

Web (Pfeiffer Vacuum): Vacuum Solutions of Electron Beam Welding

Surface Hardening

Web (The A to Z of Materials): Surface Hardening by Ion Implantation

Book: Surface Hardening of Steels: Understanding the Basics

Fuel

Web (IEEE) [2008]: Cellulose Modification by E-Beam Irradiation & its Applications

Web(Claremont Climate Report) [2010]: Irradiating the Future of Biofuel: Using Electron Beam Irradiation Pretreatment to Improve Cellulosic Biofuel Production

General

Robert W. Hamm and Marianne E. Hamm, Eds., “Introduction to the Beam Business” in Industrial Accelerators and their Applications (World Scientific, Singapore, 2012), ISBN-13 978-981-4307-04-8.